Chemical recycling in the waste hierarchy

What is the waste hierarchy and where does chemical recycling fit?

The blog post discusses the waste hierarchy, how chemical recycling fits within it, and how each contribute to a circular economy. Chemical recycling helps us move towards a circular plastics economy by taking end of life plastics and creating valuable circular products. While chemical recycling is an important part of the transition to circular plastics, the waste hierarchy is integral for framing how chemical recycling fits into the bigger system of materials.

The Waste Hierarchy

The Ellen MacArthur Foundation defines the circular economy with three key principles – the elimination of waste and pollution, the circulation of products and materials at their highest value for as long as possible, and the regeneration of nature. The Waste Hierarchy provides a practical framework to implement this and prioritise efforts to achieve these principles.

The Waste Hierarchy is a set of guidelines for decision-making when looking at the design and end-of-life options for materials, showing which solutions should be prioritised based on maximizing the preservation of value and minimizing energy and material loss. It is important to recognize that we should shift our thinking from simply “waste” to, where possible, recognise materials as valuable resources. The goal is to maximize the value of these resources, rather than treating them as disposable.

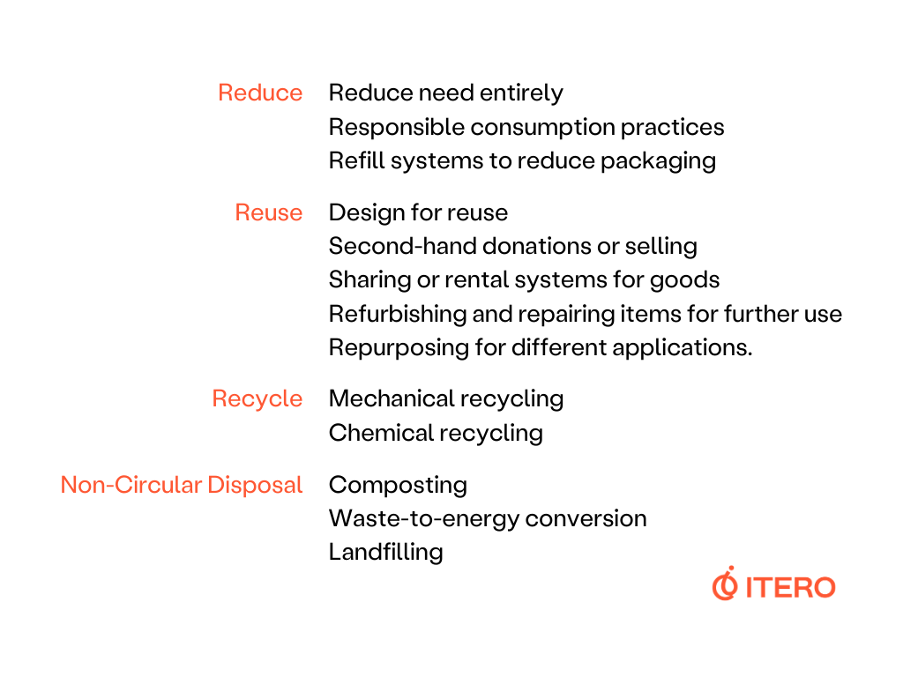

The waste hierarchy can be simplified into four main categories: at the top and most prioritised is prevention and reduction, followed in priority by reuse, and then recycling, and lastly non-circular disposal. Only products that cannot be feasibly reduced should be made for reuse, and only those that cannot be feasibly reused should then be designed for recyclability, and only products that cannot be recycled should be disposed in ways that are not circular. Currently, there is a large volume of mixed and low-quality plastic feedstock that cannot be mechanically recycled effectively or economically and thus must be disposed of through incineration or landfilling. In a fully circular economy, various chemical recycling solutions could end the need for this.

To advance towards a circular economy, we must rapidly accelerate the scaling of recent innovations in reuse and recycling, with priority given to circular solutions higher in priority on the waste hierarchy. However, there are challenges in how best to implement the waste hierarchy, with debate alongside rigorous analysis and policy guidance to support the balance between sustainability and circularity, taking in factors of environmental damage and sustainability concerns. For example, while reduction of plastic usage reduces the amount of plastic waste needing to be processed, oftentimes substitution of plastic packaging with paper or cardboard can result in a higher carbon footprint.

Chemical Recycling within the Waste Hierarchy

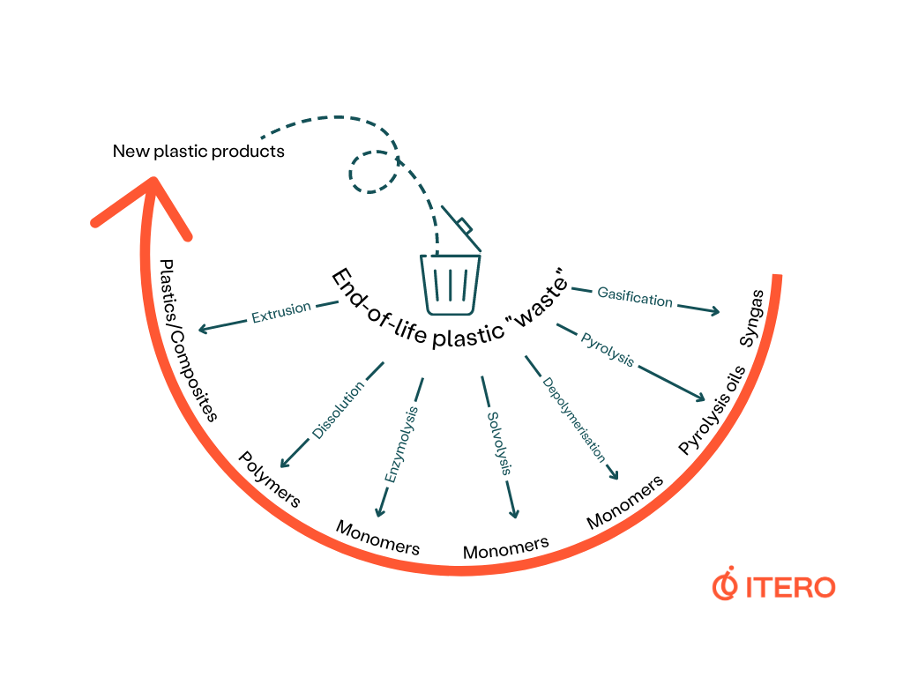

Chemical recycling is an umbrella term for a diverse family of technologies that play an important part of advancing the circular economy. The various technologies encompassed by chemical recycling work by breaking down plastic waste into its basic molecules, feedstocks which can be turned into virgin-quality plastic. Unlike mechanical recycling, which is limited by the type and quality of plastic feedstock it can process effectively, chemical recycling can generally handle a broader range of plastic waste, including mixed and low-quality feedstock that would otherwise end up in landfills or incineration. Chemical recycling takes feedstock economically or physically unable to be accepted by mechanical recycling, and so comes further down the waste hierarchy. The result is that chemical recycling creates a circular solution for plastics that would otherwise be disposed of in landfills or incineration, extending their life and keeping their value in the economy.

It's important to understand that chemical recycling is not a single technology for a single type of plastic, but a wide range of technologies that creates products to be used at different stages of the plastic production pipeline. A wide range of chemical recycling technologies is needed to address the diverse array of plastic waste, each designed to handle different plastic specifications and variations. This diversity of technologies ensures that we can effectively process various types of plastic waste, maximizing resource recovery and minimizing environmental impacts.

Currently, a significant portion of plastic waste is collected through recycling bins and processed through mechanical recycling. If we either expand the range of plastics collected through recycling bins or expand the sorting process to include municipal waste, we can access even more feedstock for chemical recycling. This means that materials that cannot be processed through either mechanical recycling could be directed towards other circular solutions, like chemical recycling, ensuring that as much value as possible is retained within the system, before moving on to more linear solutions.

Chemical recycling fills in a current gap in the waste hierarchy, allowing us to move towards plastic circularity. At Itero we believe that by keeping more plastics in the economy, chemical recycling helps achieve the principles of a circular economy as defined by the Ellen MacArthur Foundation: eliminating waste and pollution, circulating products and materials at their highest value, and regenerating nature (building natural capital with regenerative agriculture).

To accelerate progress towards a circular economy, we must simultaneously continue to prioritize circular solutions higher on the waste hierarchy such as reduce and reuse while closing the loops towards the bottom of the waste hierarchy.